Rollon

Quick links to catalogues

Nadella Circular System AXNR

AXNR circular system has the following outstanding advantages:

- Nadella as leader in the V guides market provides guide rollers characterized by high load capacity, stiffness and precision, necessary to obtain regular movements and accurate positioning

- Depending on the configuration, a special rod end design of connection between toothed belt and carriages provides a steady and smooth moving of entire system

- Aluminium alloy machined base directly connected to the gearbox lead to a space-saving system, meanwhile a steady and easy-mounting solution

- Customized solution and complete system are available thanks to flexible configuration

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Compact Rail

Rollon’s Compact Rail is different from all other linear bearing systems available in the market and is a simple, precision, linear bearing system that is easy and inexpensive to mount to all – even non-machined- surfaces. What’s more, Compact Rail will self-align to another rail if mounting surfaces are not perfectly parallel and is a fast (up to 9 m/s) and silent.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon General

Plus System: ELM Series, Robot Series and SC Series

Clean Room System: One Series

Smart System: E-Smart, R-Smart and S-Smart

Eco System: Eco System

Uniline System: Uniline A Series, Uniline C Series, Uniline E Series, Uniline ED Series and Uniline H Series

Precision System: TH Series, TT Series, TV Series and TK Series

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

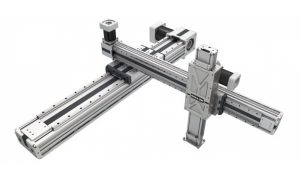

Rollon Plus System

Rollon Plus System is Rollon’s highly versatile, premier line of completely enclosed belt driven linear actuators.

The ELM series linear units are available in four sizes: 50 – 65 – 80-110 mm. They have a self-supporting structure with a robust profile of extruded and anodized aluminium. The thrust force is transmitted by a steel reinforced, polyurethane belt. The moving carriage is guided and supported by a linear guide system.

A polyurethane sealing strip ensures complete protection of the belt drive and linear guide system against dust, dirt and other contaminants. It avoids the fragility of other sealing systems such as stainless steel strips.

The components used for linear motion and accessories promote a “maintenance-free” system. The pulleys, bearings and drive shafts are among the most robust in the industry. The ELM is the best product for applications in very aggressive working environments that also require high speed duty cycles and position repeatability.

The ROBOT series is particularly well-suited for heavy load applications where significant carriage pitch, yaw or roll moments are applied; or for the linear conveyance of SCARA-type and 6 axis articulated arm robots on a transfer or factory automation line. As a robust, high load choice, the ROBOT Series is the linear actuator for the most demanding applications.

Available in four sizes from 100 mm to 220 mm, the ROBOT series linear units have a rigid structure made by a heavy rectangular cross-section of extruded and anodized aluminium. The thrust force is transmitted by a steel reinforced polyurethane. The carriage is running on two parallel linear guides with four self-lubricated “maintenance-free” caged ball bearing blocks, positioned to support the carriage and all incident loads and moments.

A polyurethane sealing strip ensures complete protection of the driving belt against dirt, chips, liquids and other contaminants.

The ROBOT series is the clear choice for heavy, high-speed, fluctuating load and moment applications in aggressive environments where repeatable, maintenance-free industrial automation is required.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Telescopic Guides Automation

In the most advanced automation systems, such as industrial machines or automated warehouses, telescopic rails are used for cantilever extractions of mobile parts, and frequently operate under critical conditions such as heavy loads, stressful cycles or dirty environments. If engineers want to obtain the best results possible, they need to choose the right rail. In addition to the technical features, they will also want to consider some variables connected to the use and motion profile, for example: rail orientation, type of stroke, accelerations and maintenance options.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon O-Rail

The roller linear system O-Rail offers the maximum flexibility configuration due to the original shape of the guide with 3 raceways arranged at 90 ° to each other where on each of those can slide rollers R..43G series. Using a single guide, two, or more parallel guides, gives rise to a number of combinations capable of satisfying each specific need for linear motion and offering exceptional self-alignment capacity. O-Rail is constructed in high strength steel hardened with hardening treatments, for a further improvement of both performance and durability.

O-Rail is designed to be a strong and simple multitask linear system for larger handling and automation applications. It is an easy to assemble system, that offers smooth motion even on inaccurate surfaces.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Speedy Rail

Rollon Speedy Rail beam is a heat-treated aluminium alloy profile with hollow cross-sections which makes it very strong under torsion and deflection stresses. Beams are then subject to a special patented treatment which provides a smooth, hard (700 HV) surface comparable to tempered steel. The fusion point of the non-stick surface layer (2100°C) permits an excellent resistance to welding splatters. For these reasons the Speedy Rail® beams and components are widely used in the automotive industry to build transfer systems (lift & carry) for automated welding lines.

Features and user benefits:

- Wide range of linear transport applications

- Standard modular components

- All parts reusable

- Minimum space required

- Narrow profile

- Hard surface

- Resistance to welding splatters

- Quiet smooth operations

- Resistance to high corrosion

- Easy to assemble

- Saving in assembly time

- Strong, lightweight

- Savings in reducing drive size

- Only hand tools required to assemble or modify

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Prismatic Rail

The Prismatic Rail product family is composed of roller sliders sliding on V-shaped rails made of hardened steel. These linear guides also have high self-alignment properties. V-shaped rails are induction hardened and polished, available in three sizes: 28, 35 and 55 mm. Antioxidation treatment is available upon request on every version. Rails can be machined with two straight cuts, one straight and one slanting cut or two slanting cuts. These options allow to create joinable versions, and thus obtaining longer strokes. The aluminium slider can be configured with a variable number of rollers with steel pins, ranging from 2 to 6. Rollers are in turn available in two variants, cylindrical or V-shaped, with variable diameter from Ø30 a Ø62 depending on rail size.

The most important characteristics:

- Long life thanks to hardened raceways

- Optimal reliability in dirty environments

- Self-aligning system

- Simple mounting

- High dynamics

Preferred areas of application:

- Robot and handling systems

- Industrial automation

- Logistics

- Packaging machines

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

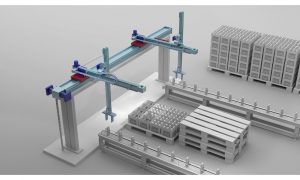

Rollon Robot Transfer Unit

Robot Transfer Unit improves your robots’ productivity by extending their operating range. Robot Transfer (or 7th Axis) Unit can move any type of robot weighting up to 1500kg over long distances with a high range of dynamics.

Discover the 8 main advantages:

- Easily integrated with any type of robot

- High stiffness with low weight

- Simplified mounting and alignment

- Potentially infinite strokes

- Protection for every work environment

- High quality components

- Full range of accessories

- Reliability backed by our experience

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Sys

Rollon Sys linear transfer system consists of higher mechanical performances aluminium alloy rail with deep anodising surface and light alloy extruded roller slides.

- Extremely small section sizes

- Modularity of the system achieved by structural profiles and wide range of accessories

- Special profile section to protect sliding tracks and roller

- Slow friction lame contact roller

- High resistance polyamide roller surface

- Customizable solutions for the applied loads

Applications such as handling units, Cartesian robots and lift and shift systems are implemented in the following sectors: wood working industry, body in white welding lines, white goods industry, piping and sheet metal working industry.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Tecline

Rollon Tecline linear system range is suitable for the handling of loads from 10 up to 1000 kg, by manufacturing one or more axis systems according to the customer requirements.

Our main application fields are: robotics, palletization, production line, logistics and manufacturing machines with Cartesian axis movements.

Our products stand out for their:

- Easy and quick assembly

- High quality and competitive performances (profiles up to 12 m)

- Reduced and simplified maintenance

- Wide range of integrated solutions

- Possibility of customised solutions

- Constant technical support and CAD drawings available

Our Tecline linears strong points are:

- Solid beams obtained from aluminium alloy extruded profiles

- High-performance aluminium casting alloy plate and preset for tool assembly

- Adapting plate suitable for any commercial available gearboxes

- Fixed and oscillating roller slides, which can be adjusted through an eccentric bushing

- Without play and sealed rollers with a “for life” lubricating system

- Tempered or induction hardened and machined strong V-shaped steel guide rails

- Adjustable limit stops provided with rubber buffers

- Wide range of accessories for 3 or more axis linears

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Gantry Stage Systems

Tecline

Linear axes with rack and pinion transmission. Rolling on trapezoidal or recirculating ball guides. High loads and precision positioning. Can be equipped with multiple independent carriages.

Modline Z

Vertical axes with belt transmission. It includes axes with pneumatic counter balance. The pneumatic cylinder is integrated inside the section, which also contains cable conduit. It requires smaller geared motors, it offers higher performances, resulting in cost and energy savigs.

Prismatic Rail

Prismatic steel guides hardened and ground with high carbon content provides for easy assembly and low maintenance requirements. Extremely adaptable, they allow for applications with good accuracy in environments with process contamination.

Modline

Linear axis with belt drive or screw drive. Rolling on trapezoidal, round or recirculating ball guides. Reduced maintenance, silent. Covers resist contamination.

Sys

Modular handling system consisting of aircraft aluminum alloy guides with high mechanical features and hardcoat anodized surface (deep, hard anodisation) and wheel-based rolling blocks. Designed to protect the wheels, it has a small cross-section and is available in various configurations depending on loads and distance between the various supports. Can be integrated with structural sections and a wide range of accessories.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Actuator Product Overview Line

Tecline

Linear axes with rack and pinion transmission. Rolling on trapezoidal or recirculating ball guides. High loads and precision positioning. Can be equipped with multiple independent carriages.

Modline

Linear axis with belt drive or screw drive. Rolling trapezoidal, round or recirculating ball guides. Reduced maintenance, silent. Covers resist contamination.

Modline Z

Vertical axes with belt transmission. It includes axes with pneumatic counter balance. The pneumatic cylinder is integrated inside the section, which also contains cable conduit. It requires small geared motors, it offers high performances, resulting in cost and energy savings.

Sys

Modular handling system consisting of aircraft aluminum alloy guides with high mechanical features and hard coast anodized surface (deep, hard anodisation) and wheel-based rolling blocks. Designed to protect the wheels, it has a small cross-section and is available in various configurations depending on loads and distance between the various supports. Can be integrated with structural sections and a wide range of accessories.

Prismatic Rail

Prismatic steel guides hardened and ground with high carbon content provides for easy assembly and low maintenance requirements. Extremely adaptable, they allow for applications with good accuracy in environments with process contamination.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

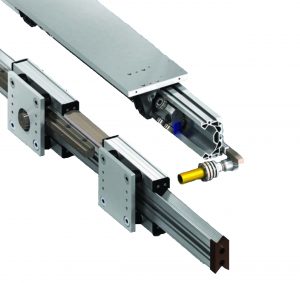

Rollon Easy Slide

Rollon Easy Slide series is a system of drawn steel linear rails with induction hardened raceways. The system consists of an “C” shaped linear profile rail, and one or more internal sliders with caged recirculating ball bearings.

The most important characteristics:

- Guide rails and sliders of SN series are made of cold-drawn bearing steel

- Ball cage is made of steel for the SN series

- Balls are made of hardened bearing steel

- Raceways of the guide rails and sliders are induction hardened (ground for the SNK series)

- Long service life

- With recirculating ball bearings for the SNK series

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Smart System

Rollon Smart Systems has the following features:

E-SMART

The E-SMART series linear units are available in four sizes: 30 – 50 – 80 -100 mm. They have a self-supporting structure with a robust profile of extruded and anodized aluminium. The thrust force is transmitted by a steel reinforced, polyurethane belt. The moving carriage is guided and supported by a recirculating ball guide system featuring one or more blocks.

R-SMART

The R-SMART series linear units are particularly suitable for: heavy loads, pulling and pushing very heavy weights, demanding work cycles, possible cantilever or gantry mounting, and operation in industrial automated lines.

The extruded and anodized aluminium self-supporting structure with a rectangular section is available in three sizes ranging from 120 to 220 mm. Transmission is achieved with a polyurethane steel reinforced driving belt. Also featured is a dual rail system with four or more recirculating ball bearing runner blocks. Multiple sliders are available to further improve load capacity.

These units are best used in applications requiring very heavy loads in extremely confined spaces, and where machines cannot be stopped to carry out ordinary system maintenance.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Eco System

Rollon Eco System units are linear actuators made of a self-supporting extruded aluminium frame and are driven by a polyurethane belt with AT metric profile steel inserts.

- Three different sizes available: 60mm, 80mm, 100mm

- Version available with recirculating ball bearing or roller rails

- Reduced weight ensured by the light frame and the aluminum sliders

- High sliding speed

The ECO SYSTEM series actuators are offered with two motion systems:

ECO SYSTEM – SP

Featuring a maintenance free recirculating linear guide rail fitted inside the profile.

ECO SYSTEM – CI

Featuring four rollers with a Gothic arch outer profile sliding on hardened steel bars placed inside the profile.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Clean Room System

Rollon Clean Room System the ONE series actuators are belt driven linear actuators specifically designed for Clean Room applications. The ONE series is certified compliant with ISO CLASS 3 (DIN EN ISO 14644-1) and CLASS 1 US FED STD 209E clean room standards by the Fraunhofer Institute IPA in Stuttgard.

The ONE series reduces particle contamination using a specially designed straight seal that isolates the internals of the actuator from the environment. In addition to particle containment, the ONE series can support a vacuum pump (up to 0,8 bar) to remove and transport contaminates from the interior of the actuator to filtration sites. The 2 vacuum ports are located on the drive and idle head.

All internal components of the ONE series actuators are designed to minimize particle release. Component materials are limited to stainless steel. Where stainless steel is not an option, special treatments are used to ensure low particle release.

Special lubrication designed for use in clean room or vacuum environments are used for all bearings and linear rails.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Curviline

Rollon’s Curviline is the cost effective linear solution for applications with linear movement that isn’t always strictly linear. It is a custom solution made according to the application needs and is obtained by an innovative manufacturing process which allows manufacture small quantities (100 pcs) in a cost effective manner.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon X-Rail

Rollon X-Rail series is a simple and cost effective linear bearing for applications where good load capacity and corrosion resistance are most important. The following are many advantages that the product offers in almost all applications: corrosion resistant even after scratching, etching and chipping; can be used in washdowns; resistant to high temperatures and temperature changes; ecological and recyclable materials.

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon Uniline System

Rollon Uniline is a family of ready-to-install linear actuators. They consist of internal Compact Rail roller sliders and steel-reinforced polyurethane belts in a rigid aluminium profile. Longitudinal seals enclose the system. This arrangement provides the best protection for the actuator from soiling and damage. In the A series, the fixed bearing rail (T-rail) is mounted horizontally in the aluminium profile. Versions with long (L) or double (D) sliders in one axis are possible.

The most important characteristics:

- Compact design

- Protected internal linear guides

- High traversing speeds

- Grease-free operation possible (depending on the application. For further information, please contact our Application Engineering department)

- High versatility

- Long strokes

- Versions with long or multiple sliders available in one linear axis

Preferred areas of application:

- Handling and automation

- Multi-axis gantries

- Packaging machines

- Cutting machines

- Displaceable panels

- Painting installations

- Welding robots

- Special machines

Technical data:

- Available sizes [mm]:

Type A: 40, 55, 75, 100 - Length and stroke tolerances:

For strokes <1 m: +0 mm to +10 mm (+0 in to 0.4 in)

For strokes >1 m: +0 mm to +15 mm (+0 in to 0.59 in)

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited

Rollon TH Series

Rollon TH linear actuators are rigid and compact, ball screw driven linear units, that enable high positioning accuracy and repeatability in all process phases. With optimal performance assured, TH actuators have a repeatability within 5 μm.

Thrust force transmission is achieved by means of super high efficient ball screws, which are available in several precision classes and a variety of leads. Linear motion is based on two or four preloaded re-circulating ball bearing blocks, with ball retainer technology, mounted on two precision aligned parallel rails. The TH series is available in single carriage or double carriage versions to meet different load requirements.

The TH linear units also feature safe rail and screw lubrication through a dedicated channel for each component. The incredibly compact structure of the TH actuator makes it the ideal solution for applications where space is limited.

- Extremely compact dimensions

- High positioning accuracy

- High load capacity and stiffness

- Preloaded ball screw

- Block with ball retainer

- Internal protected rails and ball screw

- Safe lubrication through dedicated channels for each component (block and ball screw)

Manufactured by: Rollon

Sold and Serviced by Motion Technologies Pty Limited