DSR Motion Tech

Quick links to catalogues

Drive Slew Ring (DSR)

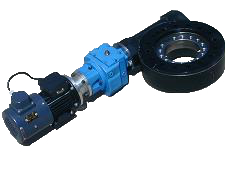

Motion Technologies has released a new design concept that integrates a worm drive gear with a slew ring.

Called Drive Slew Rings, this product is ideal for use with high torque hydraulic motor or geared electric motors.

They are available in 5 frame sizes from 3000 to 20,000 Nm output torque with enclosed or open gearing and diameters from 300 to 700 mm.

Manufactured by: Various

Sold and Serviced by Motion Technologies Pty Limited

DSR for Solar and Photovoltaic Panels

Both slew and worm products are designed and tested beyond the

customer’s static and dynamic loading scenarios to ensure that your

system maintains optimised functionality for maximum power generation. Motion Technologies offers a range of both standard and custom solutions to suit the PV and CSP Tracking industry including high efficiency AC and DC electric motors and drives to suit any system controller.

Application example:

- Solar Power Tower

- Concentrated Solar Thermal

- Solar Parabolic Trough

- Solar Dish

- Linear Fresnel Solar Concentrator

- Single-Axis Solar Tracking

- Dual-Axis Solar Tracking

- Linked Horizontal Single-Axis Tracking

- Centralized & Decentralized Single-Axis Tracking

- Utility-Scale & Distributed Solar Tracking

The catalogue below shows standard products which can be customised to suit any specific application or installation by utilising:

- Gated product development processes

- Specification development

- 3D & 2D design

- Simulation, FEA

- Engineering analysis, DFMEA

- Prototyping

- Custom test design & design verification

- Custom manufacturing

Manufactured by: Various

Sold and Serviced by Motion Technologies Pty Limited

DSR Application Compendium

Introduction

Drive slew rings consist of a slew bearing, reduction gearing (worm or spur), housing, shaft bearings and a motor in an integrated package with a hollow output bore. The motor drives the input gear shaft which in turn drives the outer ring of slew bearing causing it to rotate. The outer ring is attached to a rotating flange while the inner ring of the drive slew ring slewing bearing is fixed to the stationary housing.

Function

- Designed to carry combined axial and radial loads as well as a tilting moment

- Horizontal or vertical mounts

- Dual axis versions available

- Dual drive versions to provide very high drive torque

- Electric (AC, DC, geared) or hydraulic motors

Application

- Solar tracking for dish/array/through sung tracking

- Industrial

- Cranes

- Wheel drive

- Winch drive

- Mining equipment (eg rock grab)

- Construction Machinery (eg crane slew)

- Welding Equipment (eg manipulator)

- Automation (eg robot rotation)

Features

- 11 frames sizes, 80 to 400mm worm centre distance

- Frane OD from 152mm to 845mm

- Rated max. torque from 400 to 150,000 Nm

- Rated static radial load from 16.6 to 945 kN

- Rated static axial load from 30 to 2360 kN

- Through bore

- Low profile design

- Open or fully sealed versions

Manufactured by: Various

Sold and Serviced by Motion Technologies Pty Limited